Membrane Layer Switches Over Explained: A Comprehensive Overview to Their Advantages

Membrane layer changes represent a advanced and flexible remedy for developing customer interfaces throughout a selection of fields. As sectors increasingly seek effective and reliable control user interfaces, recognizing the details advantages and applications of membrane changes comes to be necessary.

What Are Membrane Buttons?

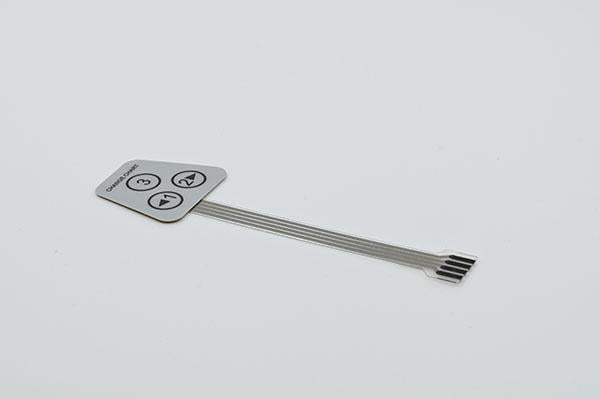

When pressure is put on the membrane button, the layers make get in touch with, finishing an electric circuit. This simple device enables for a large range of applications, from customer electronics to industrial equipment. Membrane layer buttons are commonly designed to be water-proof and immune to dust and contaminants, making them appropriate for settings where sturdiness is important.

Furthermore, the flexibility of the materials made use of in membrane layer switches over assists in cutting-edge styles that can comply with various shapes and measurements. This flexibility adds to their appeal in diverse fields, consisting of clinical tools, automobile controls, and home devices. In general, membrane changes represent a critical component in modern-day interface technology, linking the gap between users and electronic systems.

Key Advantages of Membrane Buttons

Among the myriad of individual interface choices readily available, membrane switches stand apart for their distinct combination of advantages. Among the key advantages is their light-weight and portable style, which enables combination into a large range of gadgets without adding significant mass. This is especially helpful in applications where area is limited.

Additionally, membrane layer switches over deal durability and resistance to environmental factors. They are typically created with products that can withstand moisture, dust, and different chemicals, making them suitable for extreme conditions. This sturdiness adds to a much longer life-span contrasted to typical mechanical buttons.

One more considerable advantage is the adaptability in personalization. Membrane layer switches can be printed with various graphics, colors, and appearances, permitting tailored designs that satisfy specific branding or practical needs. This adaptability includes the number of layers and circuit alternatives, providing engineers with multiple arrangements.

Additionally, the responsive responses offered by some membrane switches boosts user experience, making them a lot more instinctive to operate. Last but not least, the ease of cleaning and upkeep even more strengthens membrane layer switches as a sensible choice in both customer and commercial applications. Membrane Switches. In general, these crucial benefits make them a preferred option for several developers and producers

Applications in Different Industries

Just how do membrane layer buttons find their location throughout varied industries? Their adaptability and capability make them essential parts in industries varying from medical care to consumer electronics. In clinical gadgets, membrane layer buttons are utilized for their convenience of cleaning and resistance to contamination, making sure hygiene in atmospheres where sterility is vital.

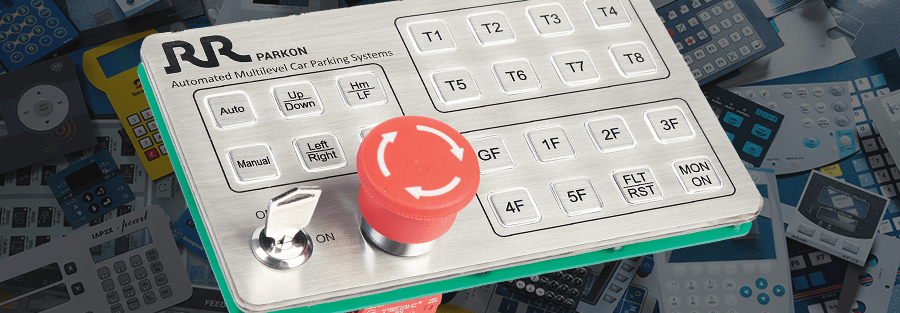

In the customer electronics industry, these switches offer streamlined, straightforward interfaces that enhance product aesthetics while keeping sturdiness versus wear and tear. Automotive applications profit from membrane layer switches too, where they are utilized in control panels and control panels, offering reputable performance in challenging conditions.

Additionally, industrial machinery employs membrane layer buttons for control board because of their effectiveness, capability to endure extreme atmospheres, and customizable layouts that provide to certain operational needs. The food industry leverages membrane layer buttons for their convenience of usage and resistance to spills, making certain functional performance in fast-paced setups.

Eventually, the versatility of membrane switches throughout these varied applications underscores their important function in modern innovation, enhancing customer interaction while meeting industry-specific needs. Their proceeded advancement assures further combination into arising fields and innovative products.

Style and Personalization Options

The style and personalization choices available for membrane layer buttons are important for customizing user interfaces to fulfill certain individual needs and visual preferences. These switches can be created in numerous shapes, dimensions, and layouts, permitting seamless assimilation into diverse applications. The flexibility in layout means that suppliers can develop one-of-a-kind user interfaces that enhance use and maintain brand identification.

Customized shades, graphics, and appearances can be applied to the surface of the membrane switch, offering an opportunity for branding and user engagement. Additionally, backlighting options, such as LED illumination, can view website be included to boost presence in low-light conditions, thus improving performance.

Useful components can additionally be customized, including tactile feedback and actuation pressure, which can be adapted to suit different individual communications. The choice of materials, such as polyester or polycarbonate, permits variations in sturdiness and ecological resistance, providing to the particular demands of various industries.

Eventually, the comprehensive layout and customization capacities of membrane layer switches make it possible for companies to develop aesthetically enticing and straightforward interfaces, ensuring that their items meet both functional and visual needs effectively. Membrane Switches.

Factors To Consider for Implementation

Applying membrane layer switches over calls for mindful consideration of numerous factors to make sure optimum functionality and individual experience. Variables such as exposure to wetness, severe temperatures, and chemical compounds can substantially impact the button's efficiency and longevity.

One more vital aspect is the switch's design and layout. Making sure that the responsive responses and actuation force align with customer assumptions boosts use. Conducting user screening can provide important insights into the optimal design.

Additionally, compatibility with electronic components must be evaluated. The switch's circuitry ought to line up with the total system architecture, making certain trustworthy signal transmission and reducing disturbance.

Additionally, manufacturing techniques and costs need to be assessed. The choice in between custom-made layouts and typical designs can affect both budget and lead time.

Last but not least, take into consideration repair and maintenance. Membrane buttons might require certain cleansing and care procedures to preserve their look and functionality with time. By attending to these considerations, companies can apply membrane switches that fulfill their functional needs check here while offering a favorable customer experience.

Verdict

In verdict, membrane layer switches represent a flexible and resilient control interface suitable for a vast variety of applications across numerous industries. Membrane Switches. As innovation proceeds to develop, the importance of membrane buttons in modern tools continues to be considerable, offering both performance and visual charm.

Membrane layer switches stand for a advanced and versatile service for developing individual interfaces throughout a range of sectors.Understanding the essential parts of modern-day electronic user interfaces, membrane buttons are a type of user interface tool that are composed of flexible, thin layers of material. Overall, membrane switches over represent an essential component in contemporary customer interface technology, connecting the void in between users and electronic systems.

Amongst the myriad of that site customer interface alternatives available, membrane changes stand out for their unique combination of benefits.The design and customization options available for membrane layer buttons are vital for customizing interfaces to meet details individual requirements and aesthetic preferences.